What challenges and troubles have you met in assembling agricultural drones? What is your solution?

As a new generation of assembled agricultural drone-Z SEREIS, what new solutions does it provide?

As the world factory, China has a strong industrial foundation and a complete industrial chain, including the supply chain of drones.Sufficient supply of components and materials, as well as public technical informations, provide local brands, insecticide services and entrepreneurs with more choices and opportunities for development.

Self-assembled drones have two attractive advantages, low cost and easy maintenance, but they have to face some technical challenges and risk costs.

First challenge, Hardware assembly

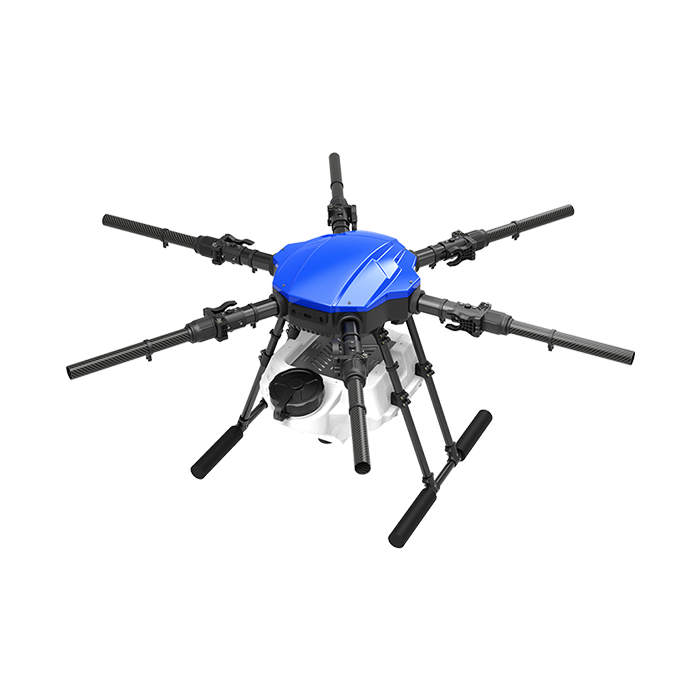

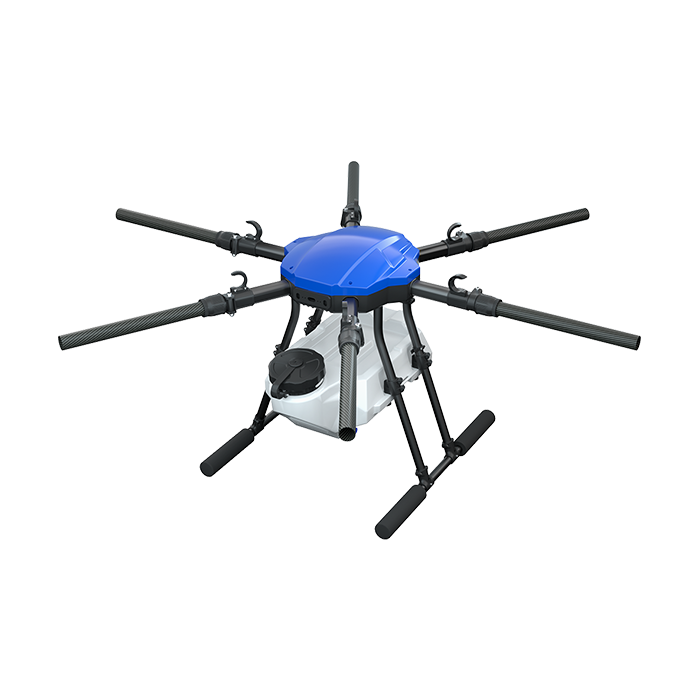

At present, most drone bodies on the market have adopted integrated injection molding to reduce the difficulty of assembly, but there are great differences in other details.For example, the unreasonable distribution of hoses on tank or many connectors , which is easy to leak or block, and it is troublesome to switch spraying and spreading; The arm connector is easy to slip or crack which will cause drone crash.Etc.

For novices, it is still difficult to assemble a complete drone, so professional training is very necessary before assembling the drone.

The pictures come from the Internet, if any infringement, please contact to delete

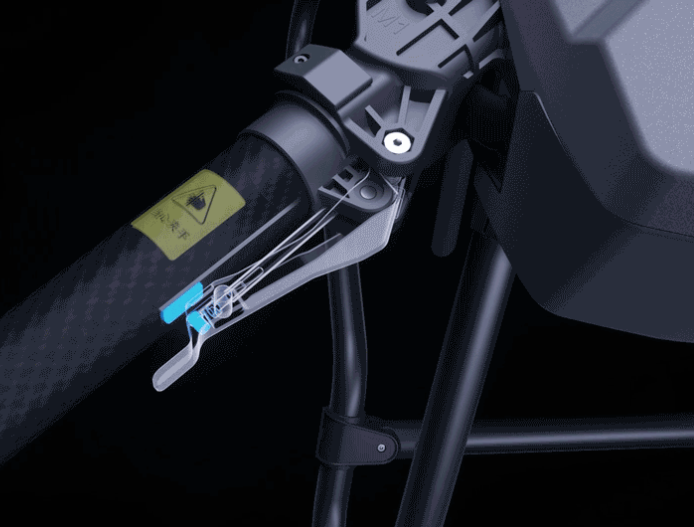

Z Series solution:

Different from other models, the Z series adopts free-tools installation designs , which greatly improves the assembly efficiency.For example, the buckle-type shell, the Press-locking handle of arm with sensor which can effectively prevent crashes caused by arm failures. Integrated spray tank, reasonable water pipe layout and few joints greatly reduce the risk of water leakage and blockage, It can quickly switch the spray system to spread system , highly improve operating efficiency.

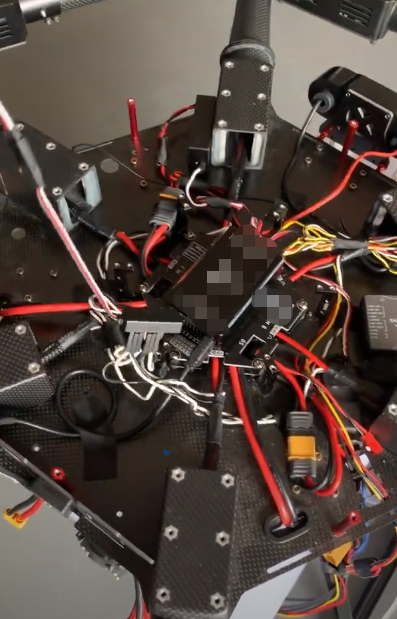

Secondly, flight control installation and debugging

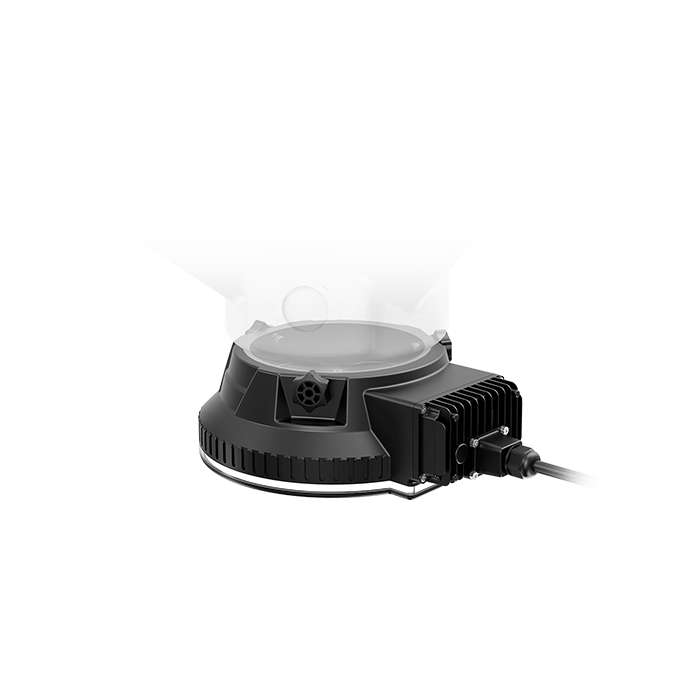

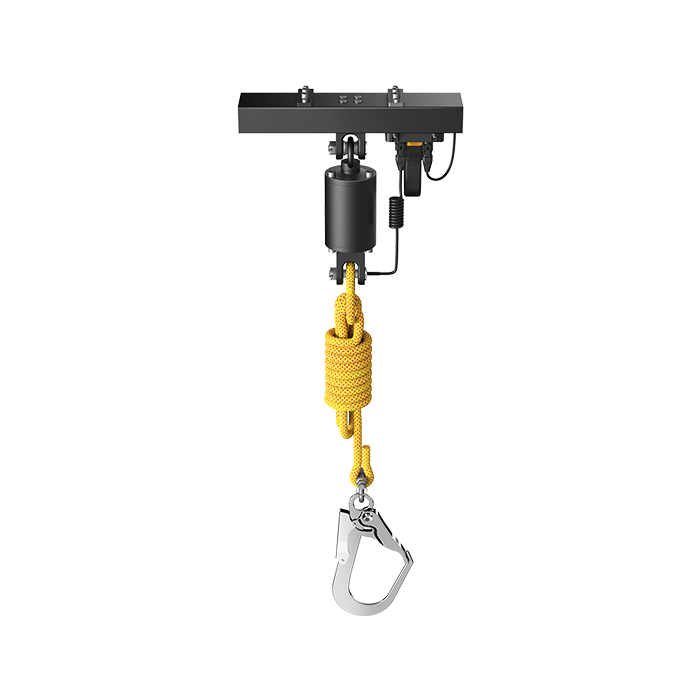

The installation and debugging of the flight control is crucial to the stability of an agricultural drone。Usually, there are many connecting wires for flight control, RTK, GPS, and radar in the assembled drone, also the motor cables ,make the cabin very messy, difficult troubleshooting,and easily wrong connection .The scattered modules often encounter incompatibility, cause some functions are unavailable and lower the performance of the whole drone.

Usually, experienced assemblers use distribution boards or labeling to organize the wiring harness. However, the operation effect and intelligence of the assembled machine are still unsatisfied.

The pictures come from the Internet, if any infringement, please contact to delete

Z Series solution:

Z series adopts pluggable flight control and group wiring board. The flight control, RTK, and receiver are integrated sealed design, Easier to install and deeply waterproof, which greatly reduces the difficulty of assembly technology and failure rate. With EFT customized firmware and protocol, smoothly interconnected of whole drone, greatly upgrade intelligent effect .

In addition, after-sales service

An assembled drone may come from multiple suppliers, the lead time of each component is difficult to coordinate, and high transportation cost.It is difficult to judge which part caused , so cannot get timely and effective solutions .This is one of the key problems that repels most small and medium-sized entrepreneur.

Some companies can purchase all configurations from agents or traders in order to save costs, but they can't enjoy professional after-sales technical services.Therefore, after-sales issues have always been a huge challenge for most brand owners.

Z Series after-sales service:

Z series full-system products have 100% testing and strict quality review, pre-installed multi-language software system .All official channels can enjoy professional technical services, let you purchase with confidence.

Technological innovation originates from life and changes life.

EFT adheres to the orientation of customer needs, constantly pushes better products. If you have new requirements or ideas for assembling agricultural drones, welcome to contact us.